Sustainable decision by RRK Wellpappenfabrik: New caliber for folding boxes and other packaging solutions

News General news

The RRK Wellpappenfabrik in Bottrop had no less than the reduction of the overall costs in complex process chains, optimization of logistics costs and the reduction of CO2 emissions as their goal when, in cooperation with a customer, they developed the previously common corrugated board folding boxes from B-flute to the test. In a close joint exchange within a very short time, the experts recognized that substitution with folding boxes based on a D-flute would produce the desired effects.

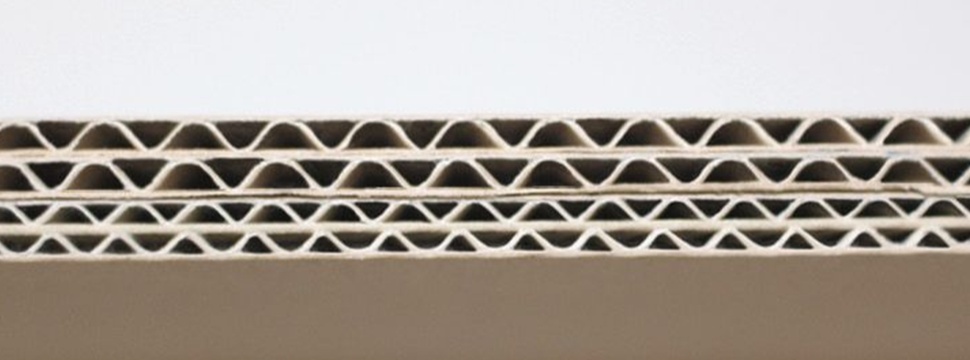

The approximately 27% reduced caliber of the D-flute (1.8 mm caliber height compared to 2.5 mm for the B flute) significantly reduces the total volume of the folding boxes for the same quantity, which also results in a significantly lower transport capacity and storage requirements are expressed. In this specific case, there are approximately 500 fewer truck trips per year for the customer to deliver their packaging (or significantly more than 100,000 truck kilometres saved) - only for the corrugated cardboard box transport. This savings potential significantly improves the ecological balance. Since the changeover to the D-flute must not result in any loss of quality or stability, the specialists at RRK Wellpappenfabrik checked all the relevant technical criteria for the applications concerned. The D-flute meets all requirements: Reliable product protection, ease of handling, stackability, stability and, of course, recycling friendliness as outstanding properties of corrugated board - all functions are fulfilled.

After the extensive calculations, it quickly became clear that a possible implementation of the proposal had to be realized in the short term in order to achieve the customer's goals in a timely manner. The support of the RRK Wellpappenfabrik consisted in the decision to invest in a D-flute corrugating roller set for the Bottrop location for the first time. After coordination with the machine supplier, the installation was scheduled and implemented for January 2023 - just two months after the first consultation with the customer.

Immediately afterwards, RRK Wellpappenfabrik started producing the D-flute on the corrugated board plant. This included formats for die-cuts, folding boxes and tableware. In practice, it quickly became apparent that the changeover went very smoothly, but the machine employees nevertheless gained important experience with some fine adjustments, which were immediately taken into account. When processing the first orders on the various machines, a sense of achievement was also quickly recorded, and the optimal processes and settings have been continuously learned and adapted in practice ever since. The decision to now meet customer requirements with folding crates made of D-flute has proven to be the right one.

Since the first days of production this year, the team at RRK Wellpappenfabrik has been gaining more experience and has been examining how other customers and projects can benefit from the advantages of the D-flute. The knowledge that, for example, the printability is better with D-flute due to different technical values and the stacking strength (BCT) differs from that of B-flute are incorporated into the examination of a possible substitution in each individual case.

The production results so far and the positive feedback from customers make those responsible at Panther very confident. The D-flute profile, which is new for the Group, can make a decisive contribution to being able to provide even better support to numerous other customers in the realization of sustainability, process and cost optimisations.