Asahi Photoproducts Unveils AWPTM CleanFlat Flexo Plate at SinoFlex

News General news

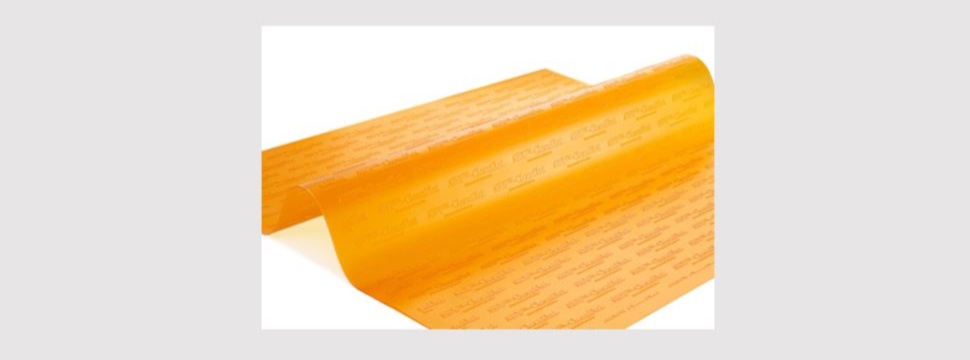

Water-washable FlatTop plate delivers high quality, consistency and improved ink laydown

Asahi Photoproducts, a pioneer in flexographic photopolymer plate development, reported successful participation in SinoFlex, Asia’s leading trade platform focusing on flexible packaging. At the show, which was held in Shanghai from 14 to 16 July, Asahi unveiled its new AWPTM CleanFlat FlatTop out-of-the-box water-washable flexo plate with CleanPrint technology, and displayed its full range of CleanPrint plates, explaining to attendees how these plates not only deliver flexo printing in harmony with the environment, but also deliver improved quality and Overall Equipment Effectiveness (OEE). Asahi CleanPrint plates are available for a wide range of applications and substrates and have been specifically developed by our chemical engineers to transfer the remaining ink to the printed substrate, reducing press stops for plate cleaning while delivering exceptional consistent quality throughout the entire run.

“We were extremely pleased with the warm reception by attendees of our line of CleanPrint plates, especially the AWPTM CleanFlat water-washable FlatTop plate that made its worldwide debut at the show,” said Ryo Ichihashi, (Manager at ASEM China). “All across Asia, flexographic printing operations are looking for more sustainable platemaking processes as focus increases on reducing their carbon footprint. Asahi’s line of CleanPrint plates ticks all the boxes in this regard.”

The Asahi AWPTM CleanFlat FlatTop plate with CleanPrint technology is used out of the box with no special workflow or equipment required. CleanFlat plates are compatible with standard workflows including UV bank light tubes, UV LED or FULL HD exposure systems as well as modern microcell screening technologies to ensure the highest level of quality and consistency throughout the print run.

Other Asahi CleanPrint plates on display at the show included:

- AWPTM-DEW, ideal for the highest quality flexo applications, including flexible packaging and labels. Designed to move away from VOC washout solvent-based plate processing, offering a cleaner alternative to the flexo industry.

- AFPTM-BFTK, a high-quality solvent wash FlatTop plate solution with best-in-class printing press consistency. These plates deliver improved ink laydown on wide web flexible packaging film, paper and label substrates in combination with solid screening patterns and keeping highlight dots at perfect quality.

- AFPTM-Leggero, super soft plates specifically designed for printing with minimal kiss-touch pressure on corrugated transport boxes, delivering minimal washboarding and good ink coverage for the utmost in quality while eliminating board crush to better protect the packaged goods.

- AFPTM-TOP, a premium hard digital flexo plate that delivers a broad colour gamut and soft tonal shades fading out to zero. Kiss-touch printing pressure facilitates repeatable print quality and fewer cleaning press stops. Compatible with high definition screening and microcell patterning technologies.

- AFPTM-TSP, the perfect plate for sticky inks and for products like pet food packaging. It is the perfect plate solution for most sticky ink formulations, allowing fewer press cleaning stops and consistent print quality.

- AFPTM-APC/TPC are digital and analogue plates developed for the high-quality corrugated board display and signage printing market where image quality matters. On double flute coated liner board, the plate delivers with its CleanPrint technology exceptional image printing performance with minimal dot gain flute marking.

“Visitors to our stand were pleased to see how extensive Asahi’s CleanPrint line is,” added Ryo Ichihashi, (Manager at ASEM China), “with CleanPrint plates now available for just about any flexographic application.”