Contiweb equipment instrumental in streamlined production for Rodona

News General news

Rodona estimates time-savings of 15% using the Contiweb CD-N non-stop unwinder

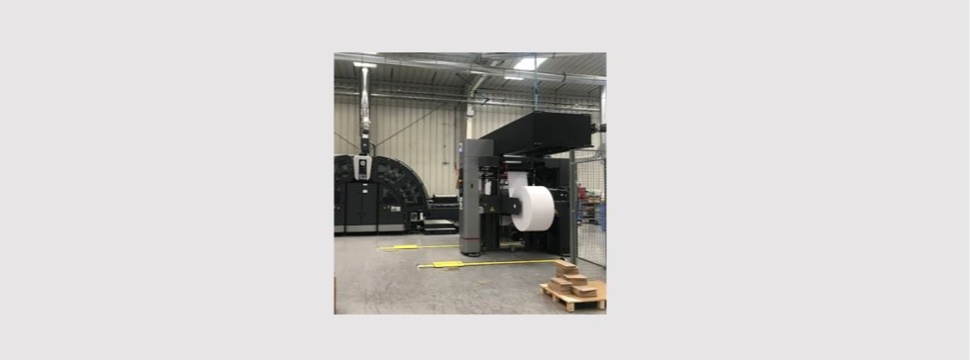

Spanish digital print service provider, Rodona Industria Grafica, has invested in a Contiweb CD-N non-stop unwinder for its Pamplona facility. The investment stems from a desire to increase digital book printing efficiency and streamline production.

Rodona Industria Gráfica, a Pamplona-based PSP specialising in digital book printing, has been in business since 2001. Originally, the business focused on the production of black and white legal books and employed offset printing. Facing the evolution of the publishing market and shorter and shorter runs, in 2010 the management decided to dismiss traditional offset printing and adopt digital web-inkjet printing of books.

Continuing its digital focus, Rodona Industria Grafica recently purchased a HP PageWide Web Press T250 HD printer and, following a recommendation of the supplier, purchased the Contiweb CD-N non-stop unwinder as a perfect accompaniment to increase production speed. It has been very common for wide HP presses to be equipped with an automatic unwinder. Rodona is one of the first customers in Europe that chose to equip the relatively small T250 press (22 inch / 55.8 cm web width) with an automatic unwinder, proving that even for a press with this web width it pays to invest in auto winding.

According to Alberto Senosiain, CEO at Rodona the most attractive aspect of the purchase is the time savings. He expands, “Any manual unwinder requires time for loading and unloading. The Contiweb CD-N non-stop unwinder eliminates that time, as all the operations are handled automatically, while the printer is in operation. Therefore, there is no need to stop the production, resulting in time savings and increased productivity. The HP T250 runs at 152 metres (500 feet) per minute. When equipped with the Contiweb automatic unwinder, it can achieve that actual speed because you don't waste time handling the changeover.

“We usually work for 24 hours a day and complete 10 to 12 reel changes a day on each printing line, which translates to three hours a day handling reel changes – that’s a significant amount of downtime. We estimate time savings of nearly 15 percent per day with the Contiweb unwinder compared to the production line where reel changing is done manually.”

Contiweb non-stop winding solutions, comprising the CD (non-stop unwinder) and CR (non-stop rewinder) series, help to increase productivity and print capacity by drastically reducing the time taken to change reels. Adding the ability to splice paper reels of different weight, web width or coating on digital inkjet presses, without stopping production, also means less reel changes are necessary.

Senosiain concludes, “We are more rapid, agile and responsive to the requests from our clients. The system is perfect for processing books with fine papers. In addition, it is also a user-friendly system, very easy to use. There has been an achievement in increased productivity and flexibility, and the ability to streamline and optimise the production workflow is the real benefit.”