Conquering the New Frontier in Production Inkjet

News General news

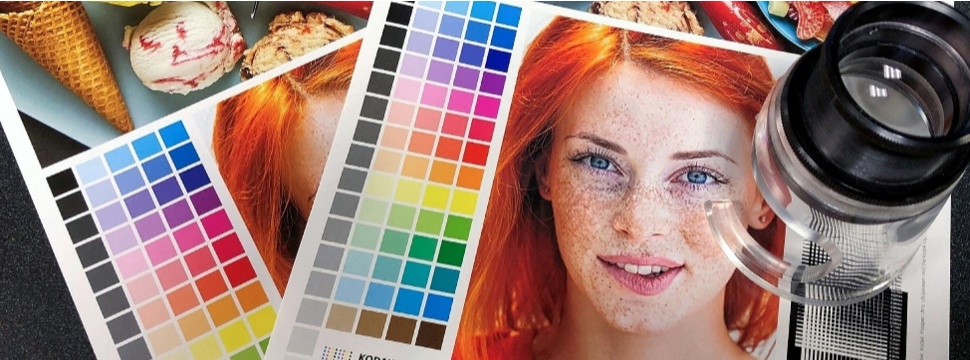

The new frontier for production inkjet is high-quality, high-coverage, graphic arts applications. The challenge in this market is to precisely place high amounts of liquid ink onto porous, and non-porous, materials and dry them at high speed without damage.

The very small number of presses serving this market is a testament to the difficulty of meeting this challenge. Today, we have a new entrant with a unique approach to delivering quality while driving up the economic equivalent order quantity between inkjet and offset.

The KODAK PROSPER ULTRA 520 four color, web-fed inkjet press takes to the graphic arts field with some key differentiators. At 500 feet per minute (FPM), the PROSPER ULTRA 520 Press is the fastest in the graphic arts sector on coated stocks. Most importantly, it delivers its full resolution at top speed, consistently for all paper weights and supported grades. While all presses in this category use aqueous inkjet, this is the only one using Continuous Inkjet (CIJ) printheads - specifically, the latest generation of KODAK ULTRASTREAM Inkjet Technology printheads that leverage electrostatic deflection to increase jetting speed and reduce the size of the print array. It is also differentiated by its use of proprietary, hardware-based screening technology to drive speed, performance, and image clarity. Let’s look at how all the components of the PROSPER ULTRA 520 Press come together to make moving volume from offset to inkjet more attractive.

Delivering Offset Quality

Among the factors that drive our perception of quality are resolution, drop size, drop uniformity, and color gamut. Resolution alone can be a deceptive indication of quality, particularly when a press supports resolutions that are higher or lower at different speeds or on different substrates. The PROSPER ULTRA 520 offers a constant resolution of 600 x 1800. Factors such as the size and placement of drops must also be considered in the context of the stated resolution. Even the highest resolution press won’t deliver great image quality if the drops are irregularly shaped or inaccurately placed. Kodak prefers to describe image quality in terms of lines per inch (lpi), the term most used by offset professionals. Kodak’s claim of 200 lpi print quality is based on benchmarking against sheet-fed offset using a Kodak platesetter with KODAK SQUARESPOT Imaging Technology. While a focus on lpi reduces the need to dig into the ways that resolution, drop size, gray levels, and bit depth work together, I want to take a moment to focus on drop formation and accuracy.

It should be self-evident that, when drops aren’t exactly on target, images can become blurry, and edges can lose their sharpness. What may be less evident is the effect of the shape and uniformity of the drop. When a drop is perfectly round, and smaller than four picoliters, it can deliver precise results. Drops with trailing satellites or artifacts suffer from some of the same challenges as inaccurately placed drops because some of the ink is trailing the target area for that drop. Satellites can form when the drop is hit by the air drag of the paper moving beneath the print head. The slower the jetting velocity, the more impact air drag will have on drop formation.

KODAK ULTRASTREAM Inkjet Technology, which is the foundation of the PROSPER ULTRA 520 Press, places 3.75 pL drops precisely and without satellites. Unlike drop-on-demand printheads, CIJ printheads produce a curtain of drops inside the printhead. With ULTRASTREAM heads, some drops are printed while others are electrostatically deflected. Each drop has the opportunity to “tailgate” on the drop in front of it and doesn’t experience any drag or loss of velocity until it leaves the printhead. While the ULTRASTREAM heads fire at a greater distance from the substrate than other presses, they also fire with three times the momentum. The added momentum and throwing distance have the benefits of preventing dust from flowing back up into the heads and protecting them from substrate irregularities

The combination of ULTRASTREAM heads, Kodak nanoparticulate pigment inks and enhanced drying make it possible to match 93% of Pantone® Solid Coated colors and drive an overall color gamut that is much larger than standard CMYK color spaces such as SWOP or GRACoL ISOcoatedV2 (FOGRA 39) *. Kodak Error Diffusion, screening technology that has been optimized for ULTRASTREAM heads, turns precise drops into clearer images with less grain and greater contrast. However, exceeding offset color targets and delivering superior image quality are not enough to drive page migration without a solid economic model.

Setting New Inkjet Economic Standards

Driving offset pages to inkjet requires speed, flexibility, and efficiency in addition to better-than-offset CMYK color. The PROSPER ULTRA 520 delivers industry leading productivity on glossy, matte, coated and uncoated media ranging from 42 to 270 gsm. Like most competitors in this market, pretreatment may be necessary for compatibility or best quality on some substrates.

Productivity of the press is a function of images per minute, as well as efficiency features that drive down running costs and optimize press up-time. Many of the productivity and cost-management features below are unique to the PROSPER ULTRA 520.

- CIJ heads that don’t require ink spit bars or head capping eliminate ink waste associated with drop on demand heads.

- Reliability, start-up, maintenance, and site costs are improved by CIJ heads, fewer parts, and a compact press footprint (48 ft./14.6m).

- Combined Near Infra-red (NIR) dryers and web-cooling deliver efficient drying of high ink coverage on heavy, gloss coated substrates at full speed.

- Nanoparticulate, pigment inks, that Kodak believes to be the least expensive on the market, are formulated with low levels of humectants making drying more efficient. Also absent are ink additives such as latex that can react adversely with post-coatings.

- The high levels of ultra-fine pigment may also allow color targets to be reached using a lower volume of ink than with competing presses.

- Ink costs are further reduced by the Kodak Color Toolkit which maintains the most accurate color while removing excess ink through Kodak’s proprietary ink optimization method.

- The Kodak Color Toolkit also streamlines color management and media qualification with Color Resource Packages to efficiently manage substrate calibration. Color and press settings can be stored allowing operators to restore configurations and begin production quickly between job types.

- A compact and scalable digital front end, the Kodak 900 Print Manager, can RIP all data in memory and drive the press at full speed.

- The integrated image quality system reduces paper waste during setup. Waste is further reduced by the ability to print on the ramp up and ramp down.

Optional implementation of offset style, inline auto-splicing, is simplified by positioning of printheads at a safe distance from media, which can improve uptime, reduce paper waste and streamline operator tasks.

Kodak has designed the press with an open hardware architecture for integration with pretreatment, post-coating, automated winding and splicing, and finishing. Varied workflow options, supporting job submission through piece-level tracking of finished items, such as JDF/JMF and KODAK PRINERGY Workflow are also available.

All these elements combine to optimize continuous up-time for the press and reduce consumables costs, ultimately raising the economic break-even quantity between web-fed inkjet and offset production. Kodak estimates that economic break-even levels between the PROSPER ULTRA C520 and a sheetfed litho press could be as high as 15,000 B1 sheets (240,000 thousand US letter or A4 images**) at 45% ink coverage and up to 25,000 B1 sheets (400,000 US letter images) at a lower, 15% coverage, including the typical premium for sheet format papers.

To provide further opportunities for cost-control, Kodak offers a choice of service maintenance agreements or click programs. The former has great economic benefit for high volume, multi-shift operations to realize the economies of scale inherent in the platform.

KODAK ULTRASTREAM Inkjet Technology: Creating a Platform for Continuous Improvement

The KODAK PROSPER ULTRA 520 Press is offered in two models, the PROSPER ULTRA C520, described above, which is designed to be highly competitive for high coverage jobs, and the PROSPER ULTRA P520 is intended for use with uncoated and inkjet treated papers and the relatively lower ink coverage suitable to those substrates. The P520 supports papers up to 160 gsm and uses NIR drying without additional web cooling.

Both PROSPER ULTRA 520 models will be available first in the US, Western Europe, and Japan with beta installations targeted for next quarter and full commercial availability in the fourth quarter of this year.

It bears mention that PROSPER ULTRA 520 presses are built on a true platform designed around ULTRASTREAM Inkjet Technology and the 900 Print Manager which were successfully launched in 2019 with the UTECO Sapphire EVO W packaging press. While the chassis of the PROSPER ULTRA 520 is designed to support four color channels, both ULTRASTREAM and the 900 Print Manager were design to support up to eight channels. In fact, expanded color gamut inks and digital varnish have been developed and are commercially available. The compact design of ULTRASTREAM heads is well-suited to enabling implementations with more than four colors in the future.

Today, we see the launch of a highly efficient press able to take on offset levels of coverage and deliver the strong, vibrant, consistent color quality needed to excel in the graphic arts market segment. The new frontier for inkjet is offset replacement and the KODAK PROSPER ULTRA 520 Press is well positioned to stake its claim.