Perfect folding quality thanks to machine vision

News General news

Magazines, books or brochures have a handy format, but they are usually printed on large sheets, approximately A0 format. These sheets are folded, cut and bound in folding machines. In this application report we look at a small, but very important detail of these machines, where a machine vision solution from phil-vision helps to avoid errors and rejects.

Folding machines create their products autonomously, and the physically strenuous stacking of the folded sheets is done by a robot. But what has been missing up to now for end-to-end automated finishing process is an autonomous fold quality control, because paper is difficult to handle and even the best folding machine cannot prevent individual sheets from not being folded precisely. However, an inaccurately folded sheet leads to individual pages being cut out at an angle, which is not accepted by the customer.

How can these processes be automated in future and how can the employees be relieved was the question that confronted MBO Postpress Solutions GmbH, a leading manufacturer of folding machines. Since the company does not have machine vision experience, phil-vision GmbH, an experienced system integrator, was brought on board. After an initial exchange about the task, an intensive planning phase began and in close cooperation MBO Postpress Solutions GmbH and phil-vision developed the optical fold quality control VT50, a system that is unique on the market.

High-quality and error-free folding

Large printed sheets of paper are processed by the folding machine and folded in a way that the pages of the planned product lie precisely on top of each other and in the correct order. The system ensures the multiple-folded printed sheets produced by the folding machine are folded accurately. This is achieved by measuring the distances between the cutting marks and the rear and side edges on both sides of the folded sheets. Even a single faulty fold in the sheet affects the measured distances and is detected.

If a sheet is not within the pre-set tolerance, it is ejected during production. The accepted tolerances can be set in 5 different, adjustable quality levels. If several sheets in a row are not in order, the production line switches off and the operator takes over and adjusts the folding machine accordingly. But he only has to pay attention to the folding machine in case the VT50 has detected a persistent problem with the fold quality, thus the operator has more time for other tasks.

Intensive cooperation as the key to success

It was quite a long way until the system was working satisfactorily, involving a large number of changes and adjustments. Since MBO had no machine vision specialist in-house, phil-vision took over the complete project planning. Starting with feasibility studies, through component selection, support with programming, to help with integration with the PLC.

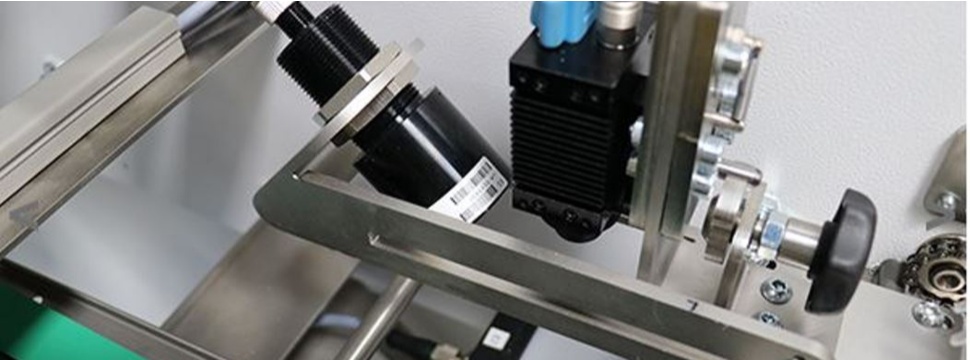

A major challenge for the machine vision system was the high speed at which measurements have to be taken. The paper sheets move at speeds of up to 180 m/min and cannot be stopped for measurement. In addition the cycle time is only approx. 0.1 seconds. At the same time, economic efficiency had to be maintained. The final system is based on two highly sensitive colour cameras that check the quality of the finished folded sheets under controlled lighting conditions with specially matched front and backlighting.

The system was first presented at the Postpress Alliance's "Cutting and Folding" theme days in June 2021 and has since proven itself in practical use.

Peter Steinbrück, the responsible project manager at phil-vision, on the challenges of the project: "During the project we had a lot of changes such as different shapes and arrangements of the marks, necessity for enlargement of the field of view, or disturbing elements in the image. The original planning of the project did not take colour control marks on the edges, smeared crop marks and partly visible page contents into account, but in the end those variations should not influence the result. The close and targeted cooperation between the development team at phil-vision and MBO was the key to the optimal solution. From the beginning, we talked very openly with each other. Therefore, the software was planned in a way that the evaluation strategy could be adapted quickly and with little effort. Due to the high cycle rate of the system, the total process time per sheet is limited to 40 ms. By choosing very simple but high-performance image-processing tools, this requirement was easily met."

Sebastian König, Head of Development at MBO, sums up the cooperation with phil-vision: "The collaboration was very professional. A lot of attention was paid to precision and details in every phase of the project. The fast response times, the project management and generally the high level of competence were very positive."