MBO wins EDP Award with Autonomous Production Line

News General news

MBO won the EDP Award 2021 in the “Finishing” category with its Autonomous Production Line. The jury of the European Digital Press Association (EDP) is made up of 21 trade journals from 27 European countries. The award stands for innovation and quality, as it is given out based on criteria such as degree of innovation, quality, costs and performance – and not on popularity. The EDP Commission press release states: “The logo of the EDP Awards stands for innovation and quality, offering orientation and providing a neutral recommendation for purchase decisions of users.”

“That’s why we are all the more pleased to have won this international competition”, emphasises MBO Head of Research & Development Sebastian König. “The prize belongs to the entire MBO team! Every one of us has made a contribution, either directly or indirectly. We are very proud“.

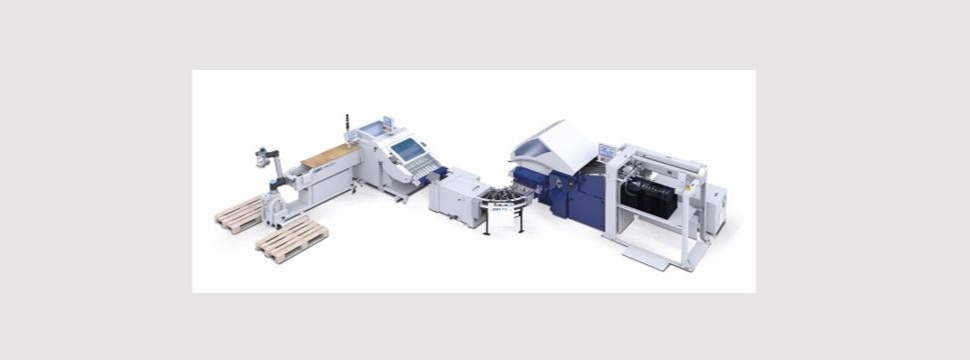

MBO has received the award for its Autonomous Production Line. This machine setup includes optical fold quality monitoring and automatic signature change. Both innovations make this finishing solution the safest, most efficient and most productive folding machine installation in the world. Work that used to be performed by the operator is now automated. Human error is now a thing of the past and the operator can attend to other work or even operate two folding machines simultaneously.

Optical fold quality monitoring

The VT50 fold quality monitoring function is located directly behind the folding machine. Two cameras in the VT50 measure the folding tolerances of the folded sheets. These tolerances can be set by the customer to fit the specific job. Incorrectly folded sheets or sheets not within the tolerance range are ejected from the outlet of the VT50. This ensures that only perfectly folded sheets are transferred to the subsequent delivery system.

Fully automatic signature change

The MBO Autonomous Production Line includes the Autopilot, which enables fully automatic signature change. The Autopilot works with a camera at the palletized feeder and processes the information from the MBO Datamanager in combination with an MIS system. The camera reads a data code that was printed on the signature in advance. Each signature gets its own code. If the signature changes, production is briefly interrupted. The A80 delivery system is informed of the signature change by Autopilot and automatically places the new signature on a new pallet using the CoBo-Stack. This prevents mixing of the folded signatures and automatically saves the counter readings.