Mondi and beck packautomaten launch FunctionalBarrier Paper solution dedicated to automated eCommerce packaging

News General news

- Mondi has partnered with beck packautomaten to launch a strong, flexible paper-based packaging solution dedicated to the eCommerce industry.

- The solution uses 95% paper and is recyclable across all European paper waste streams.

- FunctionalBarrier Paper can replace unnecessary plastic packaging, enabling shipments to arrive safely in sustainable and right-sized packaging.

Mondi, a global leader in sustainable packaging and paper, has collaborated with German machine supplier beck packautomaten to create a functional paper solution that has the potential to revolutionise eCommerce by replacing plastic packaging and creating right-sized packaging for a wide range of products.

The eCommerce market has grown significantly in recent years, accounting for approximately 20% of global retail sales in 2021. This means a wider variety of goods is being distributed, requiring packaging of different sizes, shapes and strengths. Mondi’s annual consumer trend research showed that online retailers are actively seeking packaging solutions that are practical, ensure optimal protection of goods shipped and are sustainable - 82% of customers prefer eCommerce packaging that is recyclable.

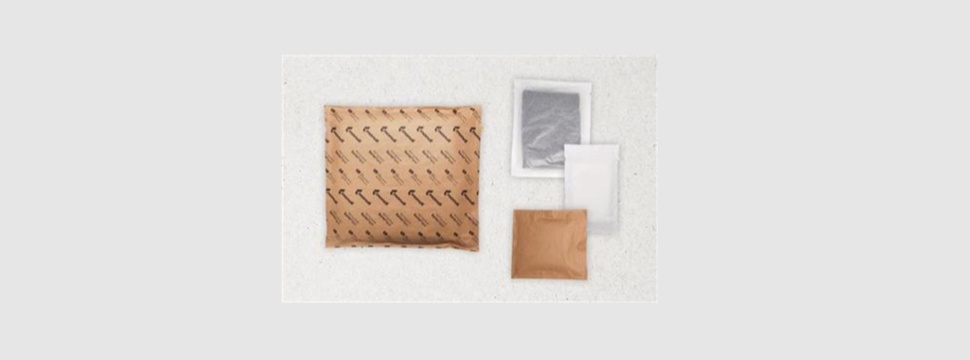

Mondi’s FunctionalBarrier Paper is 95% paper and features enhanced barrier properties to guarantee premium product protection against water vapour and moisture. This is essential for many products being shipped, including electronic goods. The paper is made with a higher strength, enabling it to carry heavier items without breakage. It is responsibly sourced, made of renewable materials and recyclable in existing recycling streams throughout Europe.

Beck’s automated packing machine ensures that products of different sizes are packed according to their requirements. The machine measures the packed goods and calculates the paper needed, reducing excess usage of the material and thereby minimising waste and costs. Stable sealing of Mondi’s paper on all four sides of the packaging ensures that it meets logistics requirements and protects goods in transit - as successfully proven during tests in Mondi’s ISTA certified lab in its Bupak plant.

"All types of goods are being transported around the globe on a daily basis. The need to create bespoke packaging that reduces waste, protects the wide range of products and delivers on sustainability targets is enormous. Our FunctionalBarrier Paper enables online retailers to continue reducing the use of unnecessary plastic following our approach of using paper where possible and plastic when useful." (Thomas Lunz, Industry Group Manager Functional Paper, Mondi Functional Paper & Films)

Alexander Deharde, Sales Director, beck packautomaten adds: “Mondi’s FunctionalBarrier Paper has excellent runnability on our automated packing lines and is a sustainable solution that replaces plastic packaging for online shipments. In a first cooperation with a European fashion retailer, we reduced plastic use significantly and will be able to save them more than 45 tonnes of plastic every year once the switch is completed.”

Mondi and beck packautomaten will present the FunctionalBarrier Paper at the LogiMAT fair from 31 May to 2 June in Stuttgart, Germany.