+Pro: Increased productivity and sustainable production with the new Efficiency Add-On for press fabrics

News General news

- Modular extension for press fabrics increases efficiency and reduces energy consumption in paper manufacturing

- Smooth non-marking surface with high wear resistance results in high-quality paper with optimal printing properties

- +Pro is compatible with all Voith Paper press fabrics

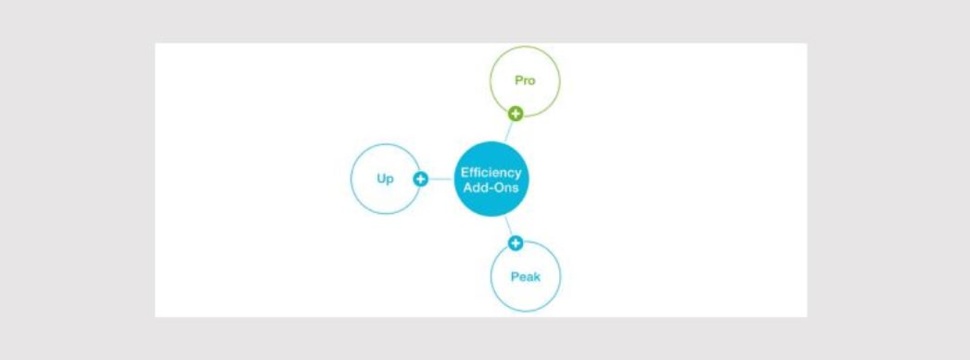

With +Pro, Voith has added another product to its range of Efficiency Add-Ons for press fabrics. Through shorter start-up times, longer life cycles and reduced wear, the modular product extensions help paper manufacturers to increase the efficiency of their machines and make the production process more sustainable.

With +Pro, the combination of a special fiber mixture and a binder system provides for an exceptionally uniform felt surface, which results in a smoother paper surface and therefore better printability of the material. A further advantage of +Pro is the more uniform pressure distribution across the entire fabric. This allows for a higher dryness in paper production and at the same time reduces the number of costly and time-consuming web breaks. The uniform pressure distribution also guarantees more stable running conditions, reduced wear on the press fabrics and therefore a longer felt life. With these qualities, +Pro provides a basis for an overall more efficient papermaking production.

In addition to +Pro, Voith currently has two other modular product extensions for press fabrics in the Efficiency Add-Ons family. +Peak has been on the market for a number of years. It is an elastomer material that is incorporated into the fabric, which reduces the start-up time of the felt and ensures a lasting high level of performance. With the same load, +Peak compresses significantly more than a standard felt. This means the felt reaches optimum functional saturation and therefore its full capacity much faster. Furthermore, it is more reliable over its entire service life than conventional products, consistently performs better and has a higher dewatering capacity. +Peak has increased the machine efficiency for numerous customers. At the same time, the improved dewatering capacity helps to increase the dry content of the web and thus lower steam consumption, which notably reduces energy consumption.

While +Pro and +Peak increase efficiency on all paper machines, +Up is an add-on optimization specifically for the needs of tissue manufacturing. The aim of the development launched in 2019 was to bring about a smoother and, above all, faster startup of the felt. In practice, the start-up time has been reduced by up to 50%. The higher saturation capability during startup allows a more stable and more quickly available capacity, which means higher overall productivity over the course of one felt cycle.

"Efficiency Add-Ons such as +Peak and +Up have already paved the way for more efficient and sustainable production on numerous paper machines worldwide. With +Pro, we have added another innovative module to this range, further helping our customers to improve the quality of their products", says Anne Klaschka, Global Product Manager Press Section, Voith Paper.