Banana paper - sustainable and ecological

News News blog

In many emerging and developing countries, paper is a luxury product that has to be imported due to the lack of forestry. Therefore, paper has been produced from the trunks of banana plants for some time now.

Each banana plant bears only one large bush of fruit per year, the so-called fruit stalk. During harvesting, not only the fruit stand is removed, but the complete upper part (pseudo-stem) of the plant is cut off. The lower stem of the banana plant remains standing, from which new bananas grow again the next year.

Nowadays, the pseudo-stem is used as raw material for banana paper. The remaining bark with small fiber remnants is dried in the sun for about 12 hours. It is then boiled in clean water until it becomes pulp. The natural juice of the pseudo-stem is so sticky that it is not necessary to add glue. Finally, the pulp is skimmed off with a sieve, pressed into a paper form and placed to dry.

The dried fibers are then woven into baskets and bags as well as packaging material.

Banana paper properties:

- Banana paper production is sustainable and ecological. No trees are cut down and the harvested product is fully recycled.

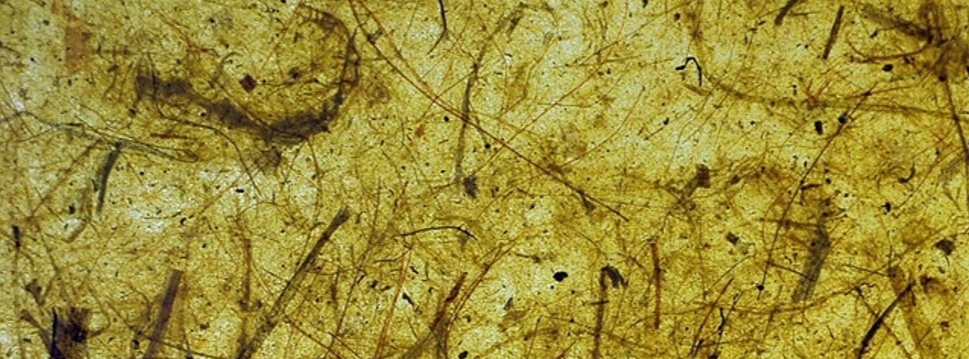

- Genuine banana paper is in the original color of beige. The shade is approximately the color of a peeled banana. Banana paper is water repellent and flame retardant.

- The handmade paper is available in a small range of colors. Natural dyes such as indigo or henna are used for dyeing. Despite the fibers, it is very easy to write and paint on banana paper.

- With a grammage of 60 g/m2, real banana paper is very thin and slightly transparent. For this reason, it is also very suitable for filigree origami motifs.