New electric steam boiler from Bosch supports a carbon-neutral future

News General news

Generate steam 100 per cent electrically

- Bosch introduces electric steam boiler

- Carbon-neutral steam generation for industrial and commercial processes

- Green portfolio from Bosch for sustainable steam and heat supply

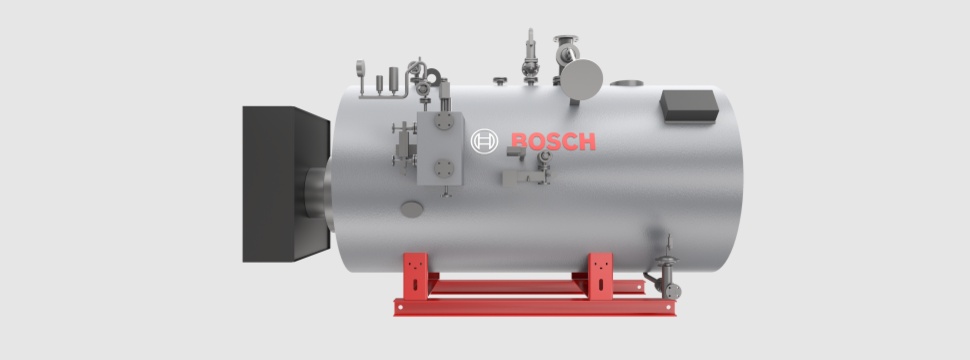

100 per cent electric and fully carbon neutral with green electricity: Bosch Industrial Boilers presents the new ELSB electric steam boiler for industrial and commercial steam generation, continuing to offer more green technologies which conserve resources, reduce emissions and protect the environment and climate. "We are making it possible for industries globally to switch to sustainable generation of process heat for a carbon-neutral future. Electrification is an important part of this," says Sven Rathmann, Managing Director of Bosch Industrial Boilers.

Thanks to various outputs from 350 to 7500 kilograms of steam per hour, the ELSB electric steam boiler meets the range of demand for industrial and commercial steam processes. An important point is that operation is fully carbon-neutral when using renewable electricity – let's look at an example of a customer in Iceland: As a pilot project, the company, which produces sustainable packaging, operates a Bosch ELSB with a steam output of 4000 kilograms per hours. The electricity used is generated from renewable sources with water and wind energy, meaning the steam generation is particularly sustainable and resource-saving. Other ELSB pilot plants have been put into operation in the food industry, for example.

With an over 99 per cent efficiency level, the electrical heating system in the ELSB steam boiler surpasses all combustion systems. Thanks to the infinitely variable output regulation, the electric boiler has the advantage of achieving an extremely high level of flexibility across the entire load range. This ensures consistently high efficiency, as well as automatically adjusting output to suit requirements or available surplus in self-generated electricity. In addition to control systems configured in-house with software, Bosch manufactures a complete steam boiler system tailored to individual requirements, covering water treatment, condensate management and modules for saving energy. Since the ELSB is operated exclusively with electricity in accordance with the power-to-heat principle, there is no need for flue gas components, chimney or fuel supply infrastructure. This saves space and costs – and no flue gas emissions are generated on site. For service-side advice, commissioning and maintenance, operators can contact the team at Bosch Industrial Service.

Not using fossil fuels and reducing CO2 make the electric steam boiler a solution fit for the future. In addition to the ELSB, Bosch also offers boiler systems for use of 100 per cent hydrogen, biofuels or hybrid solutions. Using a multi-technology approach, Bosch enables companies to model their steam and heat supply in a carbon-neutral way depending on infrastructure and individual requirements. Furthermore, it is also possible to convert existing systems to suit new requirements. This lays the foundations for a carbon-neutral future for industry, making an important contribution to the energy transition.